-

7648 Winston Street, Burnaby, BC V5A 2H4

One call, one complete solution for safer work

A complete safety solution for hazardous work starts with a comprehensive risk assessment, which determines the proper procedures, training, and PPE needed to protect workers. We the Safe brings hundreds of combined years of experience to every step of the process – one call, one complete safety solution.

Safety Consulting

We identify hazards present in the workplace, assess the risks, and determine how they can be eliminated or controlled. We help establish and implement what's required to prove your organization has taken all reasonable measures to protect workers. Our experienced consulting team manages this entire critical process – ensuring compliance and most importantly, keeping your workers safe.

Safety Education

Employers are required to provide their workers with the information, instruction, training, and supervision needed to work safely, highlighting how crucial worker and supervisor safety education is. Contact us for all your training needs, whether for new hires, experienced workers, supervisors, or management teams.

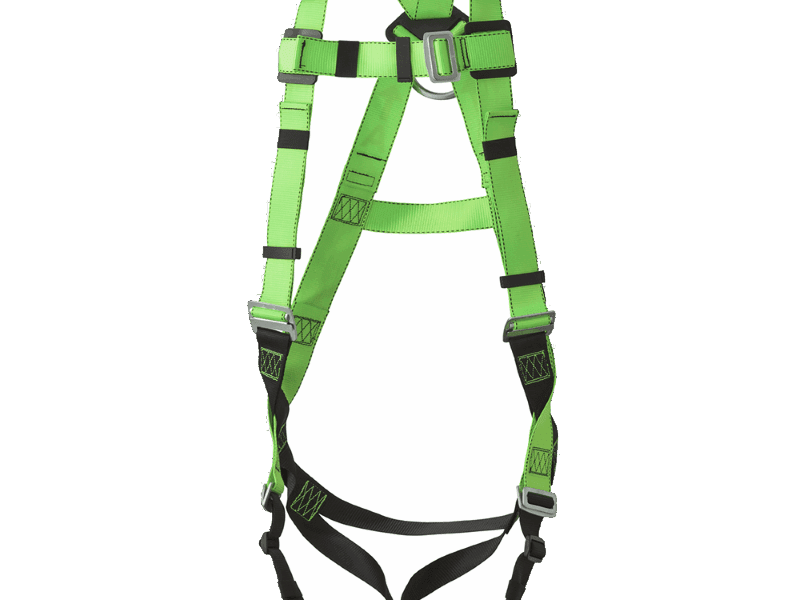

Product supply

One of the keys to an effective safety solution is the right match. Hazards must be matched with appropriate controls, and controls must be matched with the right tools and PPE. With We the Safe, training, procedures, and products are all perfectly suited to your specific needs. We offer our consultative approach to ensure you get exactly what you need for the work being performed, not just what’s available on a shelf.

Explore our Best Sellers

Do you need some help figuring out a safety management system?

It sounds like a lot of work and can be confusing. Just drop us a message. We will help you understand and in many cases you can get started on your own. Compliance is not a button to push, it’s a journey that sometimes you just need a little help to start.

QRsafety.com™ safety documents can be overwhelming

We the Safe has spent thousands of hours building and using this SwaS (software with a service). It is not safety software built by a software company, it is safety software built by a safety company.

Orientation

Hiring a worker or subcontractor without proper orientation is one of the most common, and preventable, safety failures in any industry. As an owner, prime contractor, or employer, you're responsible for ensuring everyone entering your workplace understands the hazards they'll face. An effective orientation covers both general hazards and site-specific risks, significantly reducing incidents and injuries by increasing awareness. The time invested in thorough orientations protects your workers and your safety results.

Site Inspection

Workplace inspections are required by regulation, but experienced employers know they serve a greater purpose: you can only expect what you inspect. Just as an accountant has a process to verify cash flow, safety managers and supervisors need a systematic process to verify that procedures are being followed. Documented workplace inspections provide employers with evidence that their OHS program is actively being implemented and maintained, while also driving continuous improvement in workplace safety.

Toolbox

Toolbox talks are short, focused safety meetings held directly with workers at the workplace. These collaborative sessions encourage active participation, covering topics like recent inspection findings, upcoming hazards, lessons learned from the industry or from incident reports, and any feedback or concerns from workers. Toolbox talks provide a practical approach to address issues, share knowledge, and plan ahead, keeping your team informed and engaged in their own safety.

Task/Equipment Inspection

Documented pre-use and pre-task inspections provide evidence that your OHS program is being implemented, your equipment and processes are confirmed safe, and that your teams have the required knowledge to use the equipment and do the work safely. Another common practice is inspecting work locations after task completion, which provides evidence that no hazards were left uncontrolled and the site was properly secured.

Live safe

Live long

Work at heights

Falling can be controlled; hitting the ground can be eliminated.

Hazardous environments can be managed

Being overcome by them can be eliminated

Dropped objects can be controlled

Getting struck by one can be eliminated

Have Questions?

Feel Free to Contact Us!

We will help, help you understand your responsibilities, help you get the right gear, help you get started or just help you find another company that can help when we cannot. The call is free, the results of it may be priceless.